"Why ERP didn't serve the company as much as huge investment!"

Improve your efficiency, Ask Us.

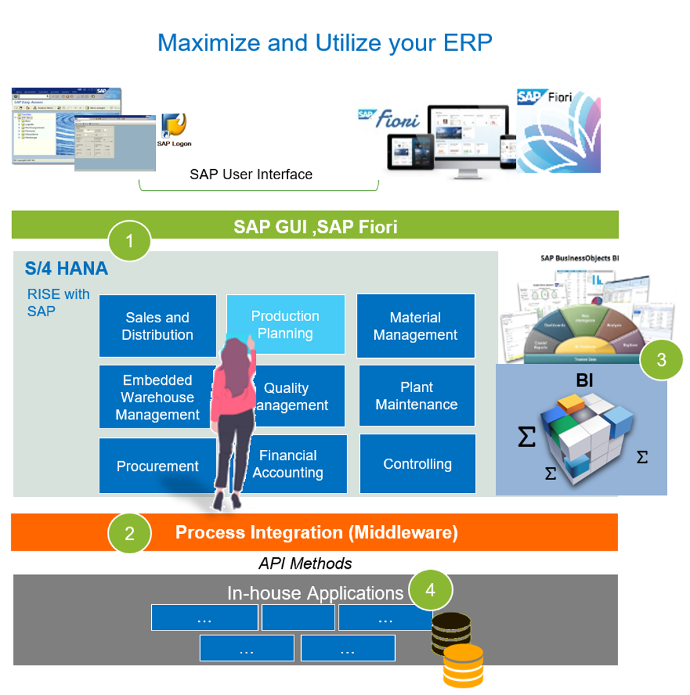

It's not that easy to be efficient ERP, is the core process we can utilize your SAP capability and interfaced with Web Application as lean process. Target to reduce the manually outside ERP, how to increase efficiency in your operations.

There is no magic, it's time to maximize utilize your IT Solution.

SAP Consultant Services

Out team have specialist in SAP Implementation more than 20 years since SAP R/3, S/4 until to SAP-BTP. So, we help to improve the functionalities and implement new processes, SAP Enhancements and include develop plug-in web engine or dev platform connect with your ERP.

Odoo - ERP Enterprise on Cloud

If you want some ERP match to you with easy to use, simply work, quick deployment, and lower cost. We introduce Odoo ERP Enterprise on Cloud, We are Odoo Partner and certified the Odoo products which we have focus SME segment who is interesting ERP Implementation, quick implementation with simply ERP integrated solution by run-on cloud platform.

DEVELOP your Platform Strategy for your Organization

. To Quick Build, Modernize Apps, Digitalize transformation with current system or your ERP. Whatever especially about huge data management or high processing execution application.

TechCode with FullStack

This is source code that AROUND have ready coding to serve you that is good, and easy to work where we want without manually is better. With our solution service that show our success story blogs.

Get what you want, where and when you want.

Supply Chain Solutions

Supply chain is the network of all the individuals, organizations, resources, activities and technology involved in the creation and sale of a product. A supply chain encompasses everything from the delivery of source materials from the supplier to the manufacturer through to its eventual delivery to the end user. The supply chain segment involved with getting the finished product from the manufacturer to the consumer is known as the distribution channel.

Supply chain management (SCM) is the oversight of materials, information and finances as they move in a process from supplier to manufacturer to wholesaler to retailer and then to the consumer. The three main flows of the supply chain are the product flow, the information flow and the finances flow. These occur across three main stages: strategy, planning and operation. SCM involves coordinating and integrating these flows both within and among companies.

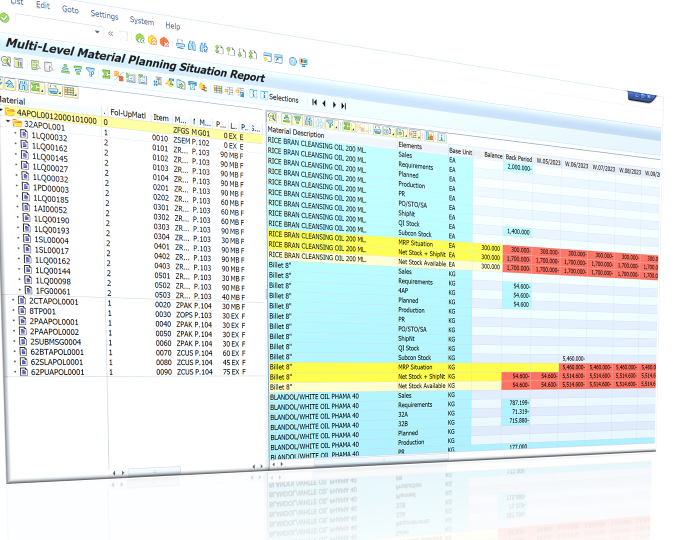

Implement SAP Material Requirement Planning (MRP)

Within the context of material requirements planning, the responsible MRP controller ensures that the materials for which he is responsible are available on time at every point in the supply chain.

The following must be provided in MRP:

- Materials and Stock Situation

- Demand and Supply balance

- Exceed or Deficit

- MRP Parameters to control results.

- Black logs visibility and monitoring

Improve SAP Production Planning and Capacity Planning

The main function of capacity leveling is to dispatch operations. Operations are dispatched for the purpose to fix them at a point in time when sufficient capacity is available. In addition to this, capacity shortfalls and overloads can be leveled with capacity leveling. You can use alternative suitable resource/work center for processing, or you can use sort the operation using graphical capacity leveling board to sort to achieve optimal loading.

Improvement P2P Process

Procure to Pay (P2P) this process stream is main process of procurement which integrated from MRP or MPS. Improvement of routine operation by automation mass execution with right materials, right time/quantity and reduce cost.

Production scheduling and sequencing

To reduce manual operation in your system, the several information required for planning, operations time, change over time, sequencing, cost, and revenue etc. We build and simplify the planning tools on ERP system that integrated demand planning and constraint of production by execute the simulation method via production matrix in system.