Capacity functional is already have in SAP but didn't use this function, AROUND provide solutions to utilize the function to adopt with your requirements.

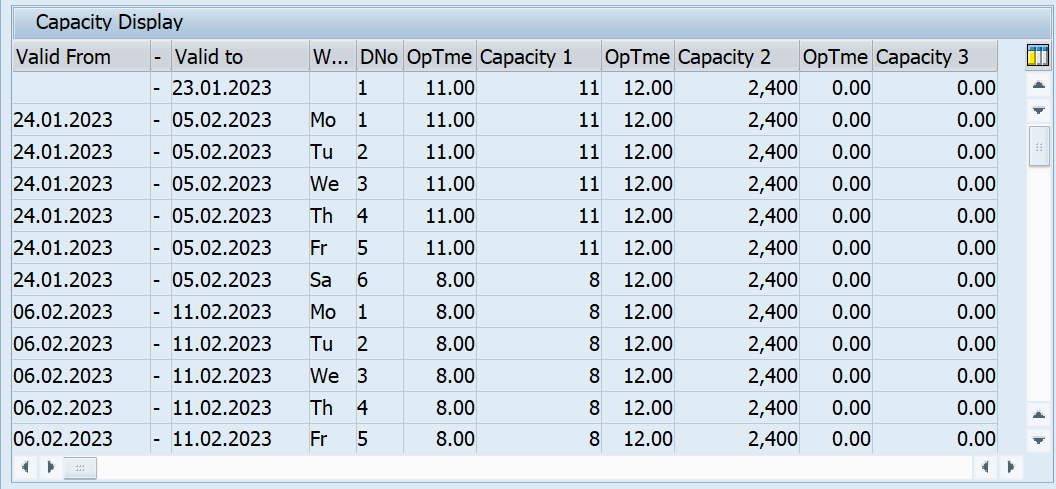

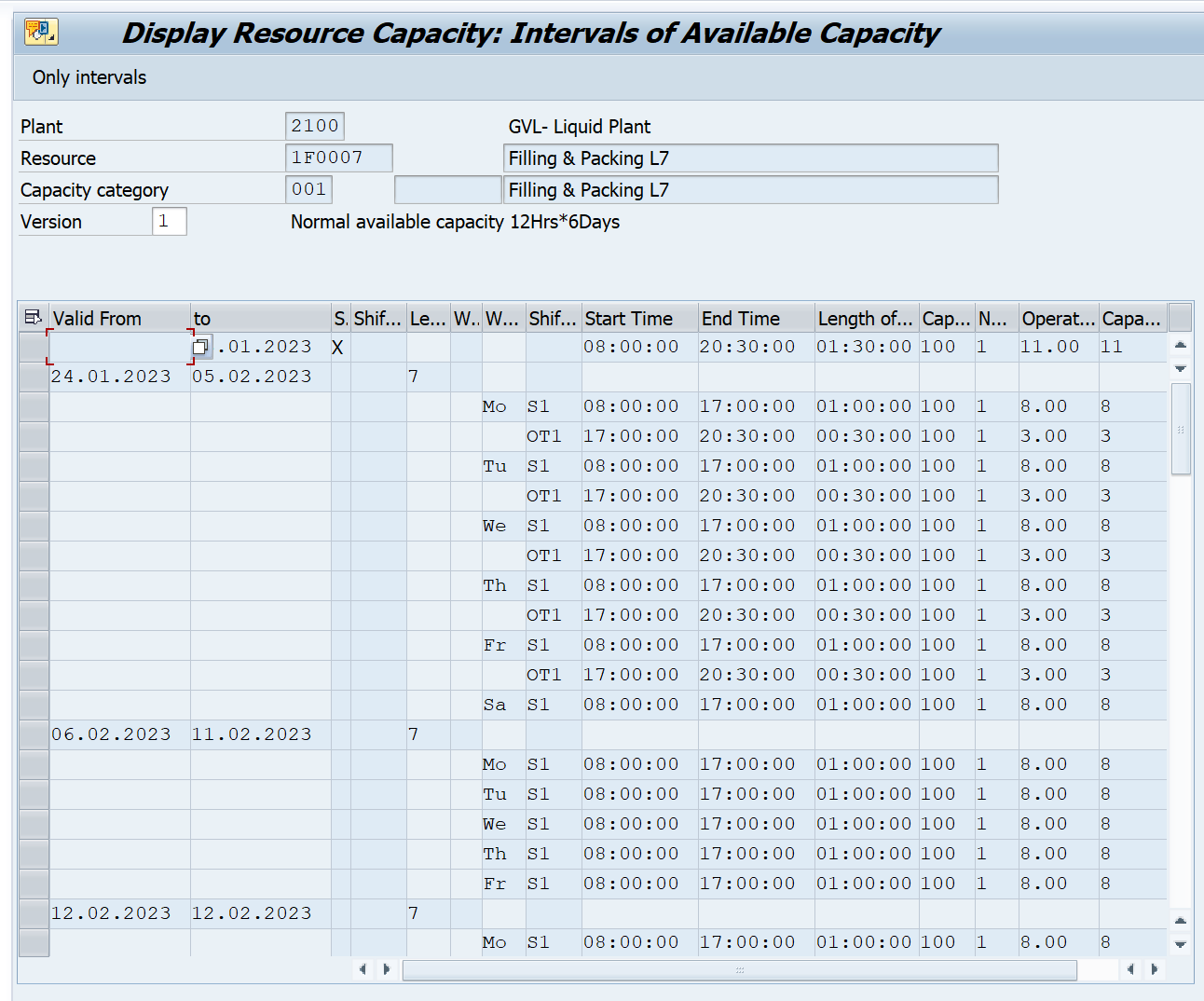

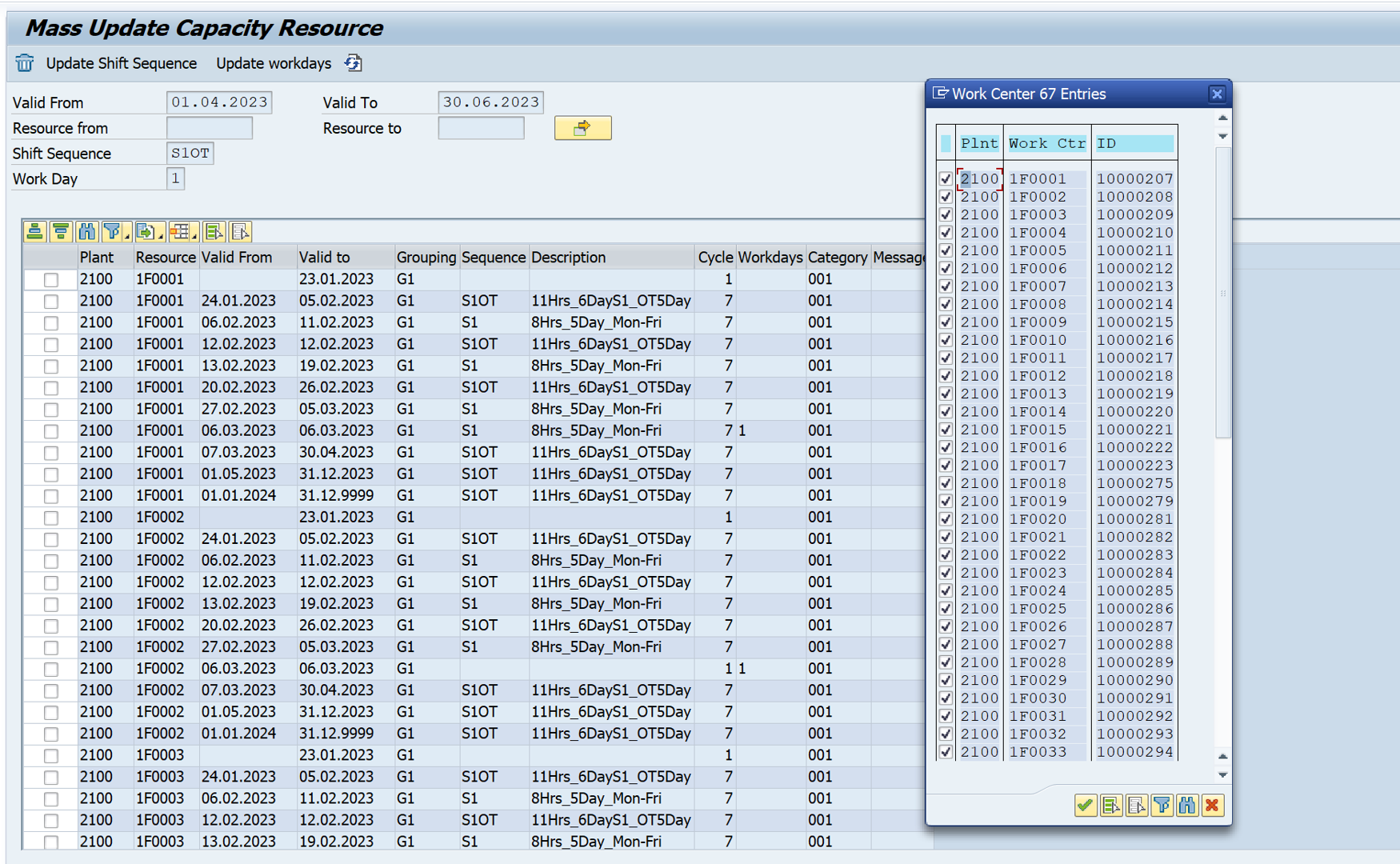

Availability capacity is defined each at work centers or resource (in PP-PI). For example, work center "WC007" is available for 40 hours each week. Which if you have many WC/resources to maintain capacity to all work centers or resources as one-by-one (not practical).

Shift pattern will mass change each period and easy to change all or as selection in the plant.

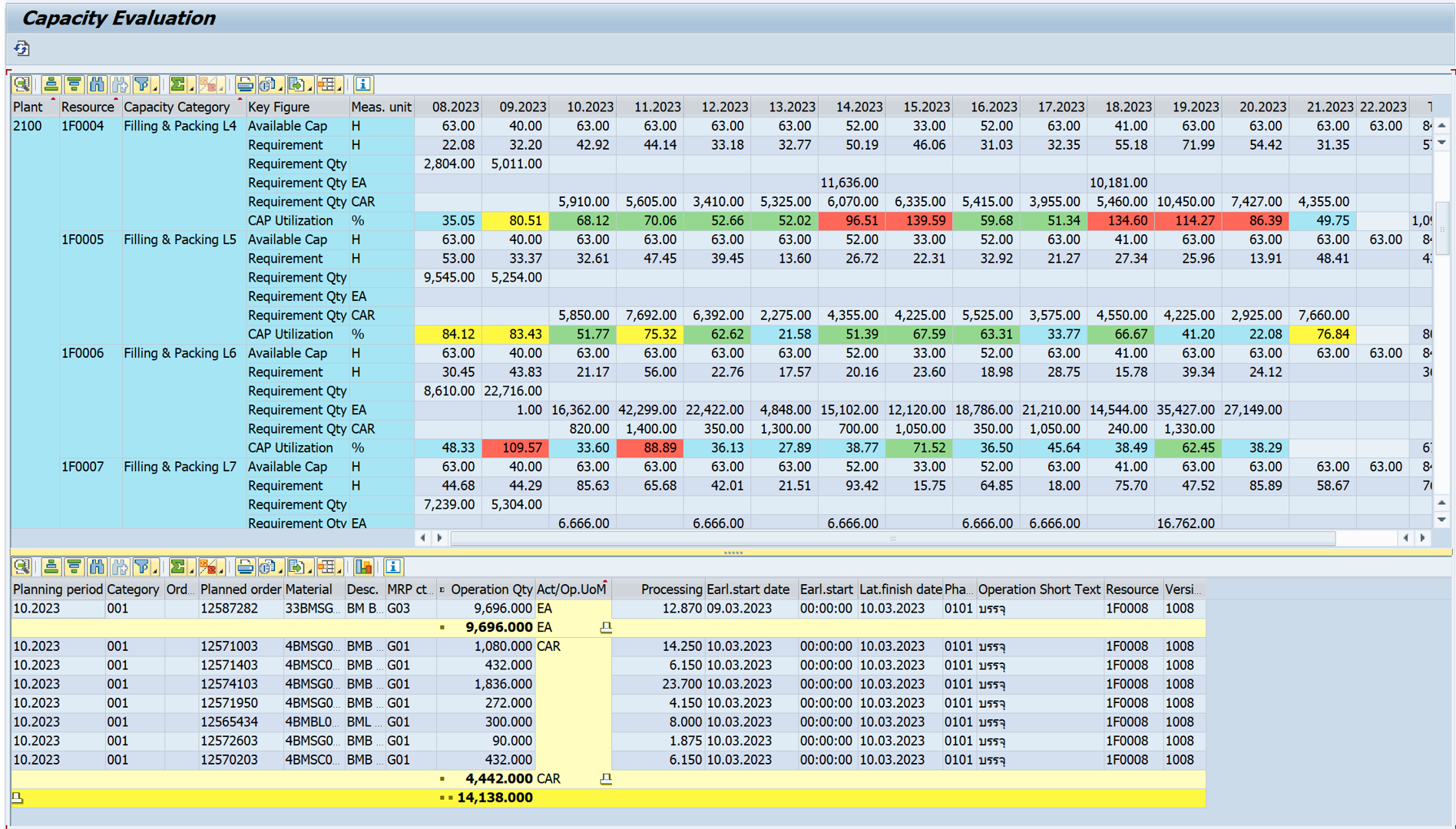

Make simplify to monitor the CRP report and The goal of capacity planning is to ensure that orders can be executed, or in other words, that work centers are available when required. Capacity planning compares the capacity requirement with the available capacity.

Because a work center may naturally be required by different orders for

completely different finished products, this comparison is usually carried

out as work center-specific.

The capacity planning generally results in date shifts because time

gaps must be found when the bottleneck resources can be scheduled.

The report show as period as you want by shift, daily, weekly or monthly. The orders (planned orders or manufacturing orders), on the other

hand, have certain capacity requirements, resulting from the routing (or

master recipe [in PP-PI]). The routing can be broken down into operations.

Each operation is assigned a work center, where it can be executed. By just double click data CAP utilization in that period will show order list in below report panel.