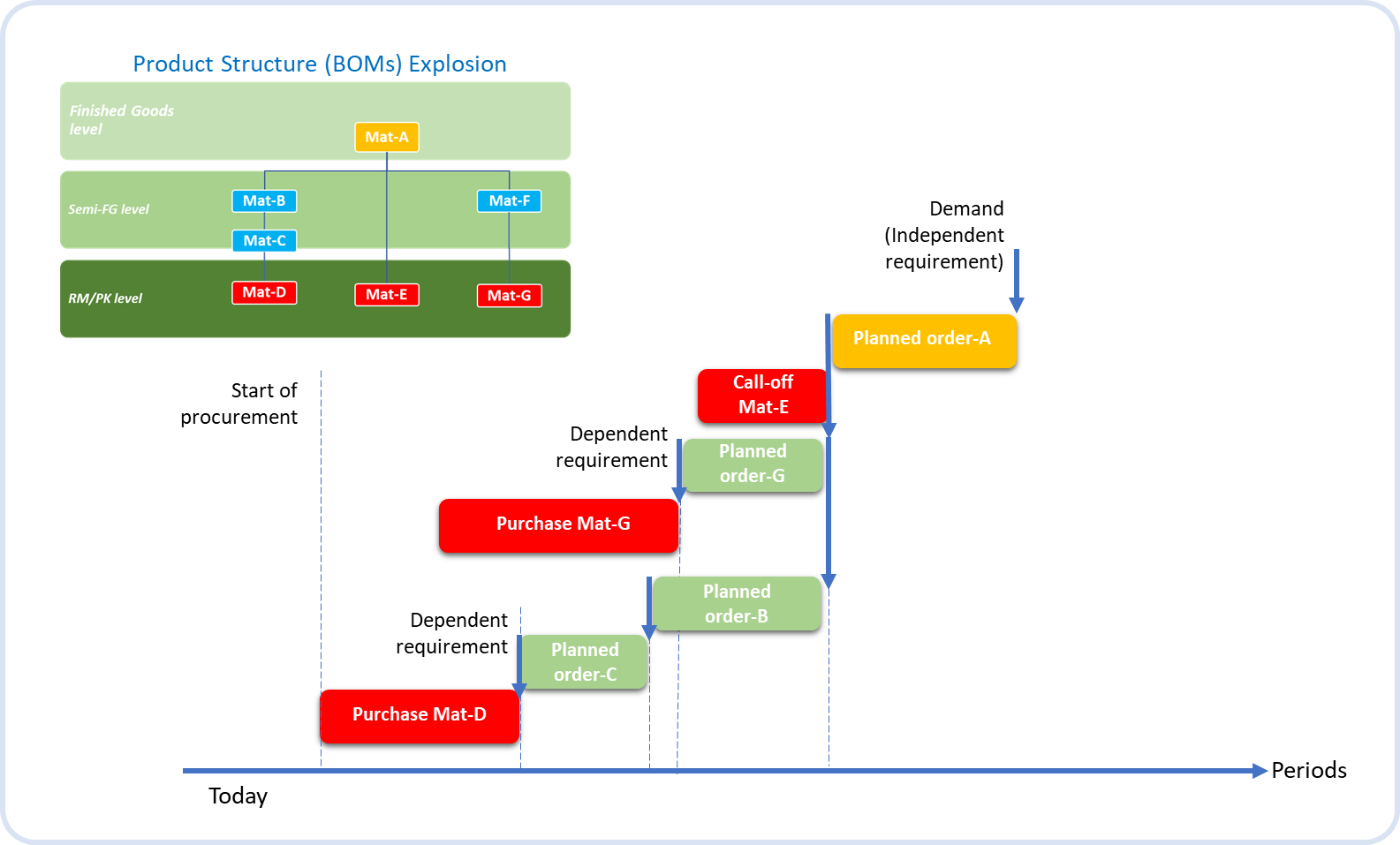

AROUND's MRP solution. The objective of MRP multilevel planning is to create procurement elements at the right time across all relevant BOM levels. The procurement dates for the assemblies and components are calculated from the BOM structure using backward scheduling from the requirements date of the finished product. This enables operation-specific material staging.

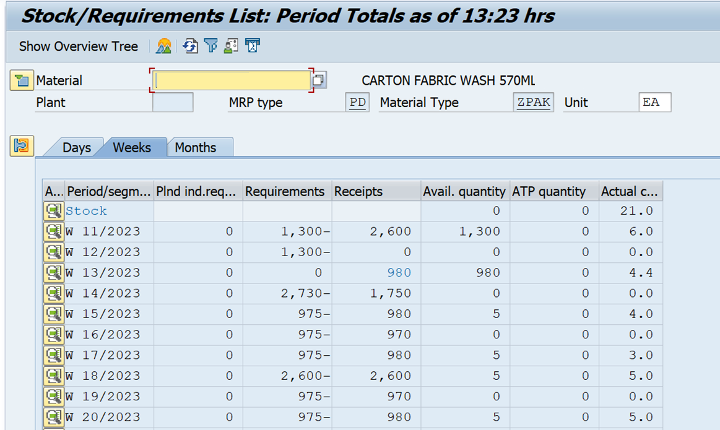

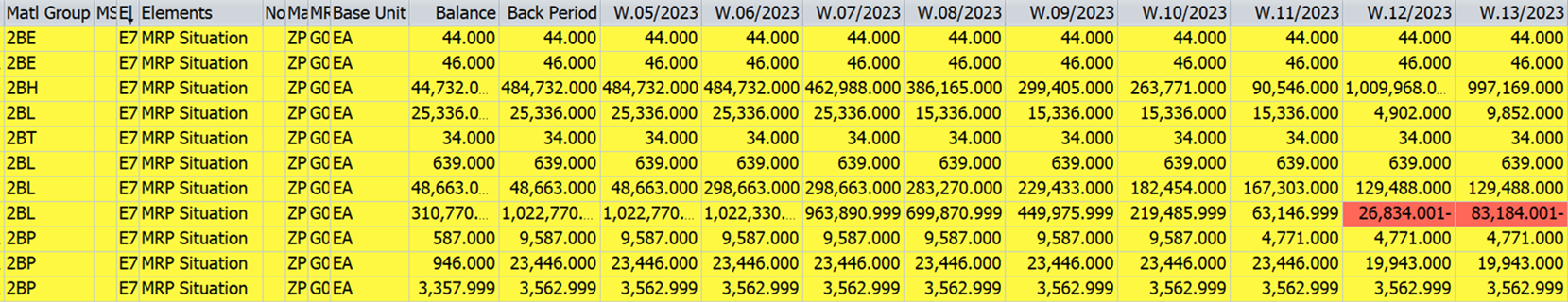

MRP Situation in MD04 (Stock/Requirement list), it click to check one-by-one materials too detailed control, this solution help to improve your MRP monitoring that ensure material availability in good time and in

sufficient quantities such as shortage or exceed the inventory.

The single material displays the stock/requirement list.

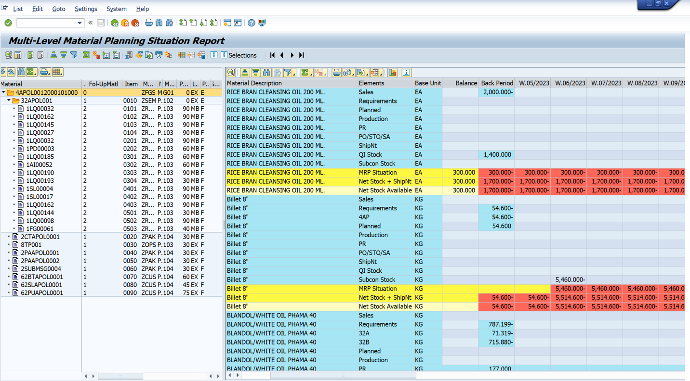

Improve MRP visibility!

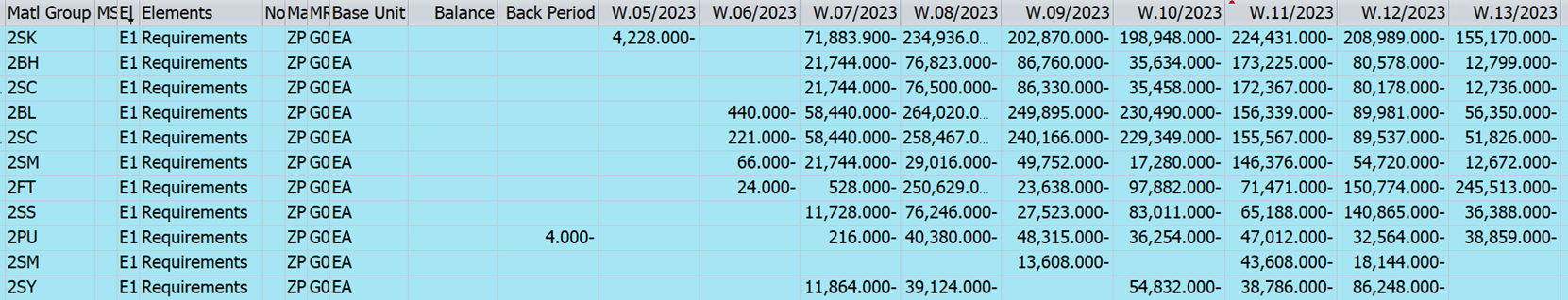

Materials by elements to see each key figure by period such as daily, weekly or monthly and sorting, filter and extraction into excel.

Alert stock situation (Exceed or Shortage)